Little Known Facts About 24hr Media.

Little Known Facts About 24hr Media.

Blog Article

How 24hr Media can Save You Time, Stress, and Money.

Table of ContentsThe Buzz on 24hr MediaSee This Report about 24hr MediaFascination About 24hr MediaNot known Facts About 24hr MediaMore About 24hr Media

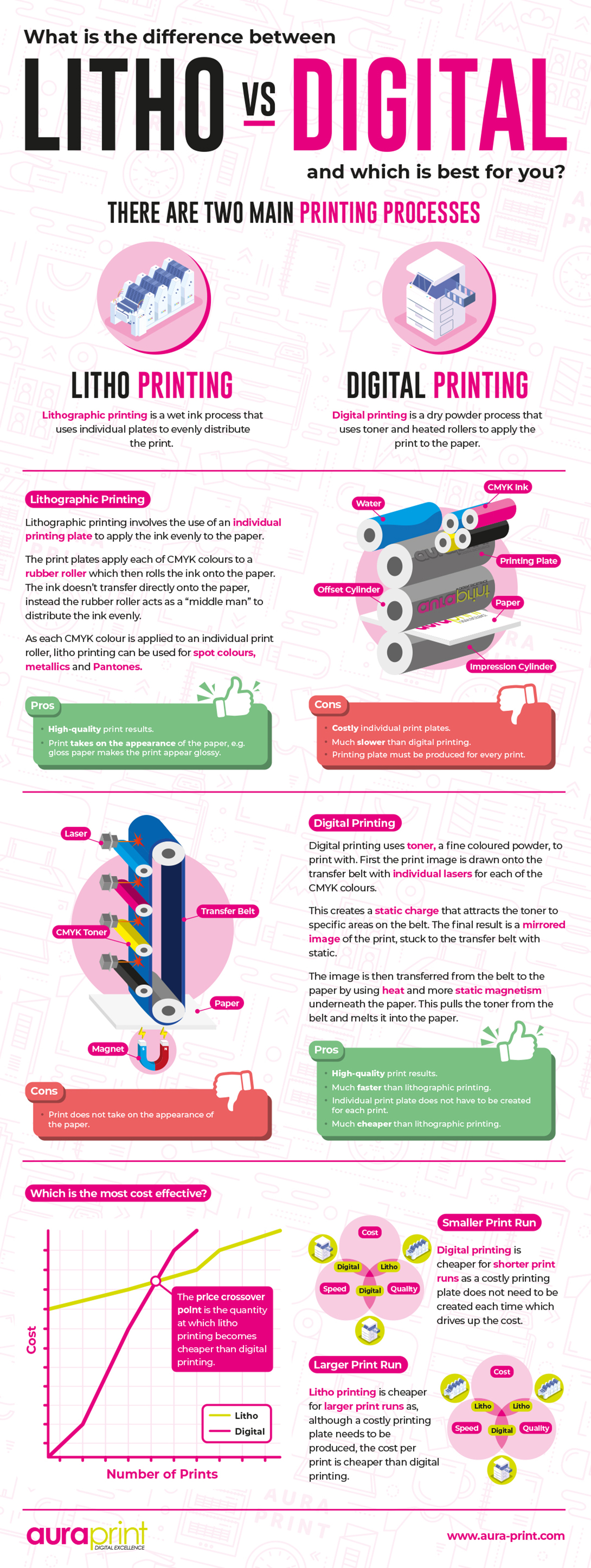

Advancements in print technology are changing the interactions playing area when it pertains to high quality, cost and cutting-edge capacities. Countered printing and digital printing are the major procedures whereby print jobs are embarked on both using four-color printing methods. Each choice has its advantages, providing various methods to meet the demands of varied production projects.

Normally, this has been one of the most consistent technique for specifically maintaining shade suits, making it perfect for print runs that only need static printing such as pre-printed kinds, brochures, flyers, calling card, and bulk postcard mailings. Nevertheless, as a result of the static nature of litho printing, it is not excellent for variable print items that will be sent by mail to individual receivers such as declarations, letters, and personalized postcards.

The Facts About 24hr Media Revealed

The latest improvements in print modern technology are helping to bring many of offset's advantages right into the electronic printing world absolutely changing the face of modern printing! There are some essential distinctions in between Offset Printing and Digital Printing.

Today's electronic print tools is amongst one of the most cutting-edge on the market. Below are some of the most significant advantages of utilizing electronic printing: dominate the electronic print area, with full-color printing finished in one procedure and flawlessly published directly from a print file. Without a prolonged set-up process, the calibration time of a certain task is shortened, adding to quicker print time and general distribution.

The inkjet printing procedure has assisted to reinvent the market in addition to the top quality and speed of the output. The current inkjet modern technology can publish on traditional countered supplies with boring, silk, and glossy finishes. High-grade electronic print coupled with software-managed color administration methods adds optimum worth to print pieces and makes manufacturing processes much more reliable than offset.

The Ultimate Guide To 24hr Media

(https://slides.com/za24media)

Exact amounts of ink and toner are used to stay clear of waste. Environment-friendly and biodegradable inks and toners are additionally readily available for even more sustainable printing. Digital print additionally eliminates the requirement to wash plates or blankets with dangerous chemicals at the end of the printing procedure. As the top quality of electronic print solutions raises, the benefits come to be progressively noticeable and beneficial.

Variable data helps companies reach their precise clients and audience with uniquely-created and personalized web content. As innovation improves, the high quality of digital printing has ended up being second-to-none, with better information, i loved this shade suit capacities and total accuracy. Without the need to wash plates or use excess ink, digital printing is also much less wasteful and typically more ecologically friendly.

Traditional printing approaches, such as balanced out lithography ("offset") and flexography ("flexo"), involve numerous make-ready steps to move an original image to a substratum. These methods call for the production of a collection of plates installed on a cyndrical tube to transfer ink that develops the desired picture when combined on paperboard and other packaging products. Digital Printing.

Getting The 24hr Media To Work

Digital printing, with less moving pieces, is more dexterous than offset in this regard.

Decreased set-up time saves cash on the front end. And since these are not enormous bulk orders, smaller organizations can manage to print without having to meet the higher and more pricey print thresholds of standard printing.

Make sure you collaborate with a printing and product packaging companion who has the right certifications. While eleventh-hour printing and modification are a huge benefit, electronic may not constantly be the ideal method for you. Offset printing has the benefit of cost-effectiveness with huge print runs, particularly those with advanced ornamental effects and specialized coverings.

Unknown Facts About 24hr Media

Lithographic presses use two print platesa favorable and a negativeto transfer top notch color graphics onto a suitable substratum. The positive plate, with its smooth surface, attracts oil-based inks and repels water. In comparison, the unfavorable plate, with its rough structure, takes in water and repels oil. Rubber rollers are after that used to transfer the photo from the plate to the corrugated surface area.

Corrugated paper can often show to be a tough surface to publish on, yet Litho prints to a separate surface area and is then laminated to it, making it easy to print high-quality pictures. It can be extremely consistent, also for futures. The more you print, the more affordable the prices become for Litho.

What Litho does not offer you is exactly what Digital does, customization. Pricey set up Longer turn-around No Variable Data Printing Smaller color gamut, colors can be less bright Digital printing is the procedure of printing digital images directly onto the corrugated substrate making use of a single-pass, direct-to-corrugate technique.

Report this page